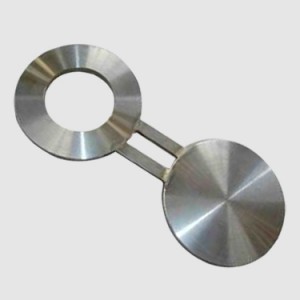

Swivel-ring Flange

Details

| Manufacturing Standards: | ANSI B16.9, ANSI B16.28, MSS-SP-43, GB/T12459-2017,ASME B16.9,SH3408,SH3409-96,SH3410-96,HG/T21635,DL/T 695,SY/T 0510,DIN 2615, EN10253-1, EN10253-2, Customized, etc |

| Size: | 1/2〞(DN15)to 60〞(DN1500) |

| Material: | CS A105/SA105N,SS 304/3034L,316/316LASTM A 182, |

| A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L | |

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining |

USE &APPLICATION

- Commonly used in the following industries:

- architecture

- bridge

- Petrochemical industry

- shipbuilding

- project

- Offshore and onshore services

- Power generation industry

- Food processing industry

Package

- Products are packaged to ensure that there is no damage during transit.

- In case of exports, standard export packaging is done in wooden cases.

- All pipes are marked with Grade, Lot No, Size, Degree and our trade mark.

- On special requests we can also, make custom marking on our products.

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

Testing

- Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

- Positive Material Identification - PMI Testing

- Chemical Analysis - Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

Certification

All materials are strictly inspected at every stage of the production process from procurement to product shipment. Visually inspect them for compliance with ASTM, ASME, MSS, DIN, EN and JIS codes and standards. Support officially certified inspection agencies to witness product material reporting, dimensional and quality compliance. Factory inspections are also supported.

Product Description

The application of swivel ring flanges is to facilitate the alignment of bolt holes between two paired flanges, which is more helpful in many situations such as the installation of large diameter pipelines, subsea or offshore pipelines, and similar environments. These types of flanges are suitable for demanding fluids in oil, gas, hydrocarbons, water, chemicals and other petrochemical and water management applications.

In the case of large diameter pipelines, the pipe is fitted with a standard butt weld flange at one end and a swivel-ring flange at the other. This works by simply rotating the swivel flange on the pipe so that the operator achieves proper alignment of the bolt holes in a very easy and faster manner.

Some of the major standards for swivel ring flanges are ASME or ANSI, DIN, BS, EN, ISO, and others. One of the most popular standards for petrochemical applications is ANSI or ASME B16.5 or ASME B16.47. Swivel flanges are flanges that can be used in all common flange standard shapes. For example, weld neck flange, slip on flange, lap joint flange, socket weld flange, plate flange, orifice flange, threaded flange, etc., in all material grades, in a wide range of sizes from 3/8" to 60", and pressures from 150 to 2500. These flanges can be easily made carbon steel flange, alloy steel flange, and stainless steels flange, etc.

In addition to the functional design of a flange, its size is the factor most likely to influence flange selection when designing, maintaining and updating a piping system. Instead, consideration must be given to the flange's interface with the pipe and the gaskets used to ensure proper sizing. We have the most professional technical team and production team to ensure that your requirements can be met and the cost can be controlled to the lowest level

Advantage