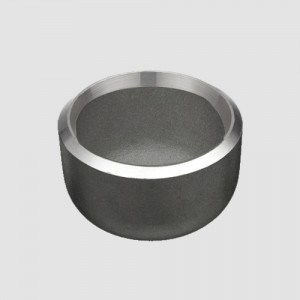

Copper Reducer

Details

| Manufacturing Standards: | ISO 9001-2015,EN 1254-1, ASTM B88M, DIN 2856, ASME B16.15,ASTM B 88M, GB/T 11618,GB/T 19228 etc. |

| Size: | Φ6-Φ42 |

| Material: | Copper |

| Use: | for refrigeration |

| Type: | Tee |

| Pack Type: | Box |

USE &APPLICATION

- Commonly used in the following industries:

- architecture

- bridge

- Petrochemical industry

- shipbuilding

- project

- Offshore and onshore services

- Power generation industry

- Food processing industry

- oil and gas industr

Package

- Products are packaged to ensure that there is no damage during transit.

- In case of exports, standard export packaging is done in wooden cases.

- All pipes are marked with Grade, Lot No, Size, Degree and our trade mark.

- On special requests we can also, make custom marking on our products.

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

Testing

- Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

- Positive Material Identification - PMI Testing

- Chemical Analysis - Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

Certification

All materials are strictly inspected at every stage of the production process from procurement to product shipment. Visually inspect them for compliance with ASTM, ASME, MSS, DIN, EN and JIS codes and standards. Support officially certified inspection agencies to witness product material reporting, dimensional and quality compliance. Factory inspections are also supported.

Product Description

The roundness of the reducer should not be greater than 1% of the outer diameter of the corresponding end, and the allowable deviation is ±3mm. The material of the reducer complies with SY/T5037, GB/T9711, GB/T8163, American standard ASTM A106/A53 GRB, API 5L, APT5CT, ASTM A105, ASTM A234, ASTM A106, DIN German standards and customer requirements.

Reducer (big and small head) is a pipe fitting used at the pipe diameter reduction point. The commonly used forming processes are reducing diameter pressing, expanding diameter pressing or reducing diameter plus expanding diameter pressing. For certain specifications of reducers, stamping can also be used.

a. Diameter reduction/diameter expansion forming

The reduction forming process of the reducer is to place a tube blank with the same diameter as the large end of the reducer into the forming mold, and by pressing the tube blank along the axial direction, the metal moves along the mold cavity and shrinks to form. According to the size of the reducer, it is divided into one-time press forming or multiple press forming.

Diameter expansion forming is to use a tube blank that is smaller than the diameter of the large end of the reducer, and use an inner punch to expand the diameter along the inner diameter of the tube blank. The diameter expansion process mainly solves the problem that the reducer with a larger diameter cannot be easily formed by diameter reduction. Sometimes, the diameter expansion and diameter reduction methods are combined according to the material and product forming needs.

During the deformation and pressing process of diameter reduction or expansion, cold pressing or hot pressing is determined according to different materials and diameter reduction conditions. Under normal circumstances, cold pressing should be used as much as possible, but hot pressing should be used when multiple diameter changes cause severe work hardening, when the wall thickness is too thick, or when alloy steel materials are used.

b. Stamping forming

In addition to using steel pipes as raw materials to produce reducers, some specifications of reducers can also be produced using steel plates using the stamping forming process. The shape of the punch used for drawing is designed with reference to the inner surface dimensions of the reducer, and the punch is used to punch and stretch the blanked steel plate into shape.

Classification

1. Divide by material:

Carbon Steel: ASTM/ASME A234 WPB, WPC

Alloy: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911, 15Mo3 15CrMoV, 35CrMoV

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM/ASME A402 WPL3-WPL 6

High Performance Steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon phosphate, PVC, PPR, RFPP (reinforced polypropylene), etc.

2. According to the production method, it can be divided into pushing, pressing, forging, casting, etc.

3. According to manufacturing standards, it can be divided into national standard, electric standard, ship standard, chemical standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

4. According to its radius of curvature: it can be divided into long radius elbow and short radius elbow. A long-radius elbow means that its radius of curvature is equal to 1.5 times the outer diameter of the pipe, that is, R=1.5D; a short-radius elbow means that its radius of curvature is equal to the outer diameter of the pipe, that is, R=1.0D. (D is the diameter of the elbow, R is the radius of curvature). 5. If divided by pressure level: there are about seventeen types, which are the same as the American pipe standards, including: Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS; Sch80, SCH100, Sch120, Sch140, Sch160, XXS; the most commonly used ones are STD and XS.

Advantage