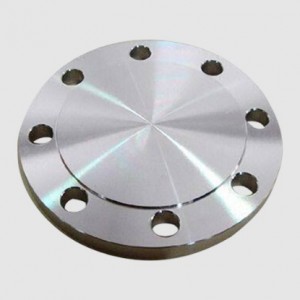

Copper Nickel Flange

Details

| Manufacturing Standards | ASME B16.5 EN1092-1 JIS B2220 HG20595-97 HG20617-97 HG/T20615-2009 HG/T20595-2009 |

| Size | 1/2〞(DN15)to 100〞(DN2500) |

| Pressure | Class150 Class300 Class600 Class900 Class1500 Class2000 PN2.5、PN6、PN10、PN16、PN25、PN40、PN63、PN100、PN160 |

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining |

| Material | C70600, C70620, C71000, C71500, C70400, C71520, C72200, HSn62-1, C37800, H68, H62, H59, TA0, TA1, TA2, TA3, TA9, TA10, TC4, TC11 |

USE &APPLICATION

- Our copper nickel flanges commonly used in the following industries:

- agriculture

- bridge

- Petrochemical industry

- shipbuilding

- project

- Offshore and onshore services

- Power generation industry

- Food processing industry

- oil and gas industr

Package

- Products are packaged to ensure that there is no damage during transit.

- In case of exports, standard export packaging is done in wooden cases.

- All pipes are marked with Grade, Lot No, Size, Degree and our trade mark.

- On special requests we can also, make custom marking on our products.

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden Boxes

Testing

- Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

- Positive Material Identification - PMI Testing

- Chemical Analysis - Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

Certification

All materials are strictly inspected at every stage of the production process from procurement to product shipment. Visually inspect them for compliance with ASTM, ASME, MSS, DIN, EN and JIS codes and standards. Support officially certified inspection agencies to witness product material reporting, dimensional and quality compliance. Factory inspections are also supported.

Product Description

Standard of copper-nickel flange

Copper nickel flange is a kind of flange connector used in ships, ocean engineering, petrochemical and other fields, and its material has good marine corrosion resistance and strength. At present, the standards of copper nickel flanges are mainly American standards, European standards, British standards, etc., of which the American standards mainly include ANSI, ASME, API, etc., and the European standards mainly include EN, DIN and so on. Within these standards, we produce plate flange, staineless steel flange, anticorrosion flange, forged orifice flange, weld neck flange, blank flange, blind flange and so on.

Second, copper nickel flange specifications and manufacturing

Copper-nickel flange specifications are divided into American and metric two kinds, commonly used size 1/2"-48". The manufacturing process mainly includes forging, machining, welding, inspection, etc. The manufacturing process requires strict requirements to ensure the strength and sealing performance of copper nickel flanges.

Third, the advantages and disadvantages of copper nickel flange

Copper nickel flange including copper nickel plat flange, copper nickel threaded flange, copper nickel screwed flange and so on, has good corrosion resistance and high strength and other advantages, suitable for use in the marine environment. However, there are also some defects, such as copper nickel flange manufacturing process is complex compare to stainless steel flange.

Fourth, the application of copper nickel flange

Copper nickel flanges are widely used in ships, marine engineering, petrochemical and other fields, such as pipelines, valves, pumps and other equipment connections. In the use of copper nickel flanges, should also pay attention to its use of temperature range, material forging state, fastening torque and other factors.

Advantage